Introducing The Next Generation In Liquid Polymer Feed Systems

State Of The Art Liquid Polymer Feed Station

Tempest 2.0 is an updated design of the polymer feed system that has proven to be an economical solution to the numerous challenges encountered in a broad range of industrial and municipal applications. Our customers have experienced real measurable benefits from our original design features. Many of our customers responded to our request for their opinions and suggestions for future Tempest versions. We incorporated their feedback in the Basis of Design for the Tempest 2.0.

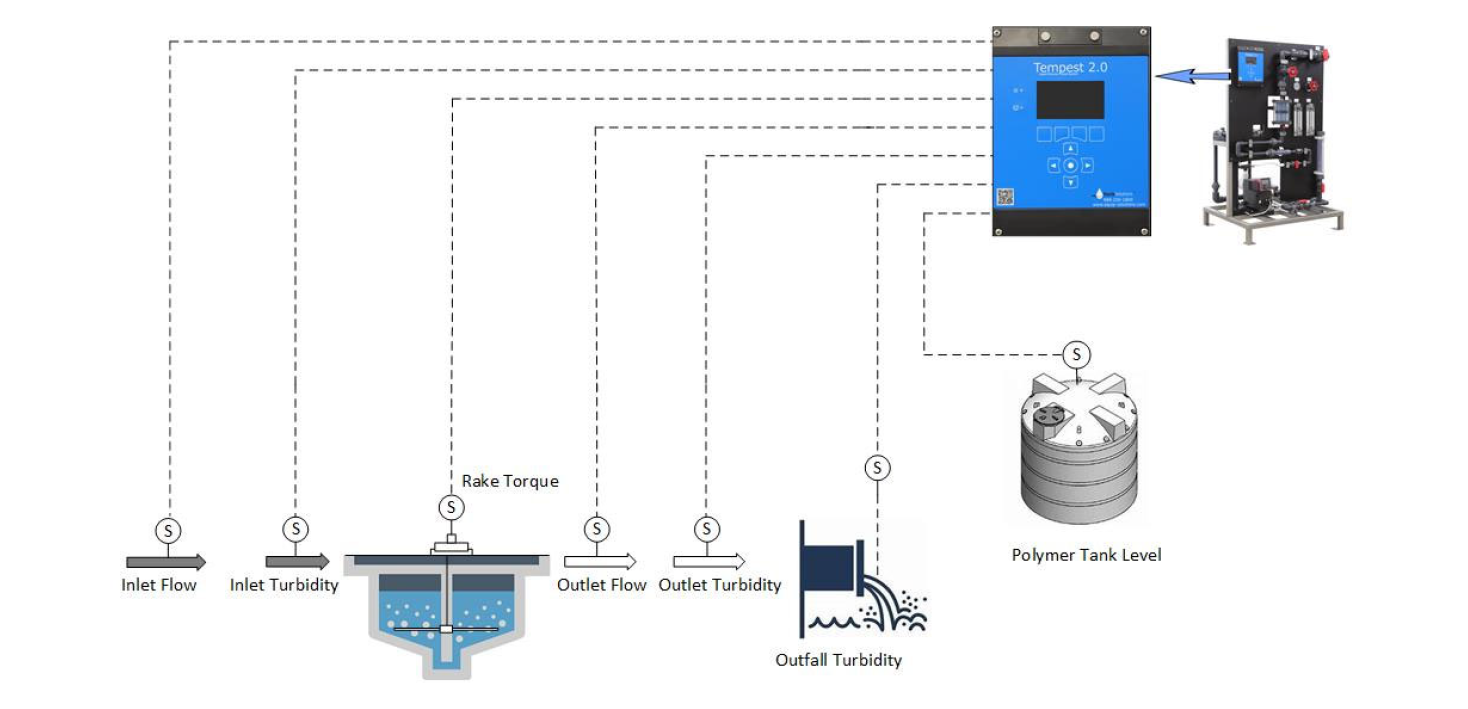

This new design integrates leading edge control technologies, expanded application capabilities, greater available I/O and seamless access to any cloud-based data acquisition system.

The Tempest 2.0 provides maximized polymer performance without the hassles and headaches these applications cause for water treatment professionals.

The Tempest T2 Controller offers significant enhancements over the original Tempest controller. Upgrades include enhanced programming options and simpler menu navigation, expanded I/O, additional communications protocols, data-logging (onboard SD card for easy data transfer), and on-screen functionality including a digital operational manual, wiring diagrams and graphing. Also new is batch tank system programming capability, tank level monitoring, and access to any third-party cloud-based portal.

Additional features include an E&H magnetic flow meter with totalizer to precisely control flow-rates, and a Grundfos DDA Series pump (a redundant pump option is available) as standard. However we can provide whichever pump our customers prefer.

Enhancements

The Tempest 2.0 provides maximized polymer performance without the hassles and headaches these applications cause for water treatment professionals.

The Tempest T2 Controller offers significant enhancements over the original Tempest controller. Upgrades include enhanced programming options and simpler menu navigation, expanded I/O, additional communications protocols, datalogging (onboard SD card for easy data transfer), and on-screen functionality including operation manual, wiring diagrams and graphing. Also new is batch tank system programming, tank level monitoring, and access to any third-party cloud-based portal.

Additional features include and E&H magnetic flow meter with totalizer to precisely control flowrates, and a Grundfos DDA Series pump (a redundant pump option is available) as standard. However we can provide whichever pump our customers prefer.

-

New State of the Art Controller

-

On Board to any Cloud Based Portal

-

Customizable Expanded I/O

-

On Screen Data Logging and Graphing

-

Versatile Comms Protocols

-

Cloud Based Remote Monitoring

-

Critical Performance Data Collection

-

Multi-Mode Operation Tailored to Application

-

Local and Remote Operation

-

Standby/ Redundant Pump Option

-

Integrated Batch System Program

-

Proven Motorless, Multi-Stage Mixing

-

Rapid Availability—In Stock

-

Pre-Programmed—Plug and Play Option

Tempest 2.0 Expandable Monitoring Tools Improve Performance

Tempest 2.0 Selection Guide

Tempest 2.0 Support Documentation and Videos