Uniquely Qualified Position

Future Growth

– First Service Call

– First Preventative Maintenance Service Contract

– First Web Based Asset Management Program

– Expand Field Service Team

– Formation of Trial Staffing Team

– Published First Equipment Catalog

– Expand Field Services Team

– Expand In-House Customer Service Team

– 25th System Installation Completed

– Formed Air Quality Control Division (CEMS)

– First MIOX Project Management Contract

– First Custom Engineered Chemical Feed System

– First International Engineered System

– Expand Service Team

– UL 508 Certification

– New Business System

– First Integrated CEMS Shelter

– LMI Distributorship

– First Major Mercury Systems Order

– Move to Turnberry Building

– Manpower Additions

– Turnberry Expansion

– Launched EZDose Configurator

– Created Concierge Service Program

– Virtual Reality Design Integration

– Introduction of the OverSite™ Cloud Based Data Acquisition Program

– Exclusive NA Supply Agreement with Process Instruments

– Concierge Service Expansion

– Introduced the Crius Controller and Accessories Line

– Expanded Technical Sales Engineering Team

– Shipped 20th Fully Integrated PLC Based Chemical Feed and Monitoring System

– 50th OverSite™ Subscription

– Resigned LMI Distributorship

– Partnered with Pulsafeeder SPO as Master Distributor

– Pulsafeeder Master Distribution Agreement

– Fully Integrated, Customer Focused Design

– 90,000 Square Foot Facility

– Customer Training Area with Workstations

– Innovation Center with Virtual Reality & Tech Showcase

– Under Roof Shelter Integration Workshops

– Large Dedicated Customer Asset Management Areas

Our success is built around a strong team of innovative individuals with the right skills, motivation, and commitment to our company's values.

We have added resources to our Application Engineering Team, Electrical and Mechanical Engineering Groups and the Customer Service staff. These folks will continue to pave the way for continued innovation and growth and ultimately our long-term success by fostering strong, support-based customer relationships.

Through the addition of state-of-the-art equipment and a staff of highly skilled certified (ASME and AWS) welding specialists we now offer precision welding services which has improved our control of quality, delivery and eliminated the threat of supply chain issues. Coupled with our engineering resources we can provide creative custom solutions for virtually any application.

Our successful problem-solving approach to tough challenges faced by peracetic acid disinfection applications has resulted in widespread acceptance of a customized equipment bundle which has been proven to minimize downtime and optimize performance of the treatment programs across a wide spectrum of applications.

Our specialized proprietary AutoFlush Controller Cabinet is a proven ironclad control platform that stands up to the harshest environments in the food processing industry.

Other industry known probes have repeatedly failed to provide accurate, consistent live readings due to severe organic fouling of the probe. Our AutoFlush Controller Cabinet eliminates the fouling issue allowing the controls to optimize chemical usage and removes the subjectivity derived from drop test titrations. Plant management now has a reliable tool that allows them to track, data log and precisely dose chemical based on a truly accurate peracetic acid ppm reading.

Applying the experience and lessons learned in these applications drove the development of a series of new multilevel coordinated equipment and service packages designed to sustain high performance, security, reliability, and efficiencies.

Our in-field application specialists have replaced dozens of DPD style free chlorine monitors with our advanced specialty analyzer. The foundation technology combines a high quality amperometric sensor and specially designed flow cell. Together these enhancements facilitate a consistent sample stream which permits accurate readings and requires minimal, once-a-year maintenance.

Our clients applaud our low recurring costs, which are a fraction of the cost of replacing expensive reagents on a monthly basis.

The combination of consistent accuracy, less maintenance required and advanced PID control are driving clients in the Data Center market to this new approach in facilities across North America.

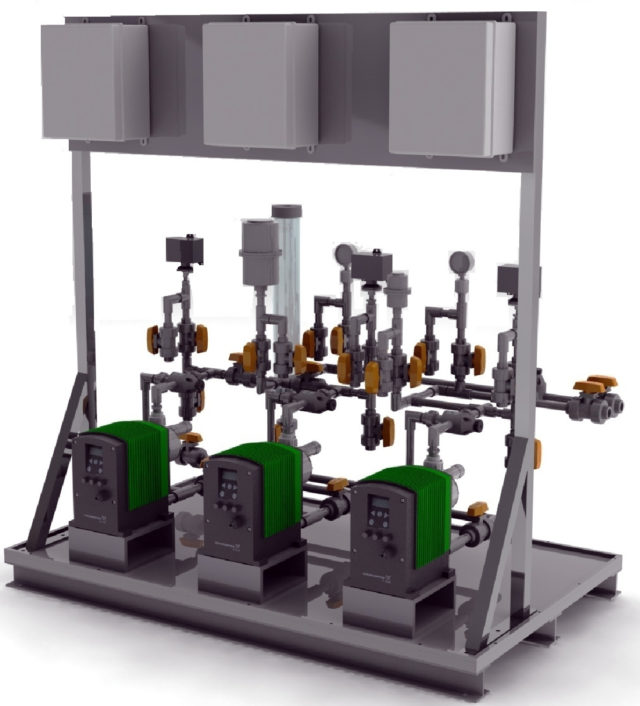

In response to customer demand, we’ve created a specialized nested workshop dedicated exclusively to the design, fabrication and testing of integrated chemical dosing and control panels.

These panels fill the need for the convenience of reliable, rapidly deployed, economical solutions for water treatment professionals across a broad spectrum of applications.