Home » Standard Products

The EquipSolutions Standard Products are the product of our research and design engineering. We manufacture, test, and service these products on an exclusive basis. This enables us to rapidly deploy and provide proven, winning technologies at a highly competitive cost.

We listened!

Feedback from our growing EZDose customer base drove an initiative of a harmonized design optimization to create a more flexible, cost-efficient design we have named our Signature Series.

Our engineering, application and service teams collaborated with our critical vendors to make design revisions which provide our clients with a broader range of metering pump options for models which are becoming more prevalent in the market.

We also examined the system control options, the physical layouts and component choices to rationalize the design for all the material choices.

We eliminated unnecessary complexity and simplified the layout wherever possible to reduce the number of components to help contain escalating costs. Download the Fact Sheet – EZDose Signature PFS0814-24

To support this innovation, we are offering a new, intuitive on-line EZDose Configurator tool.

This friendly, easy to use form-based interface allows you to navigate and configure your skid on the go, computer or on mobile! A few minutes to check a few boxes to complete the scope questionnaire allows you to build a system part number tailored to the needs of your specific application.

After you complete the form, it will be directed to our customer care team, where a team member will be assigned to assist you.

Since the EZDose Signature series is a preferred standard product, we will prepare a firm commercial quotation for the system you designed within 48 hours.

The quotation will be sent to you along with a text summary description of the system, a Piping and Instrumentation Diagram and the contact information for your application engineer. Check out the new Configurator.

Tempest 2.0 is an updated design of the polymer feed system that has proven to be an economical solution to the numerous challenges encountered in a broad range of industrial and municipal applications. Our customers have experienced real measurable benefits from our original design features. Many of our customers responded to our request for their opinions and suggestions for future Tempest versions. We incorporated their feedback in the Basis of Design for the Tempest 2.0.

This new design integrates leading edge control technologies, expanded application capabilities, greater available I/O and seamless access to any cloud-based data acquisition system.

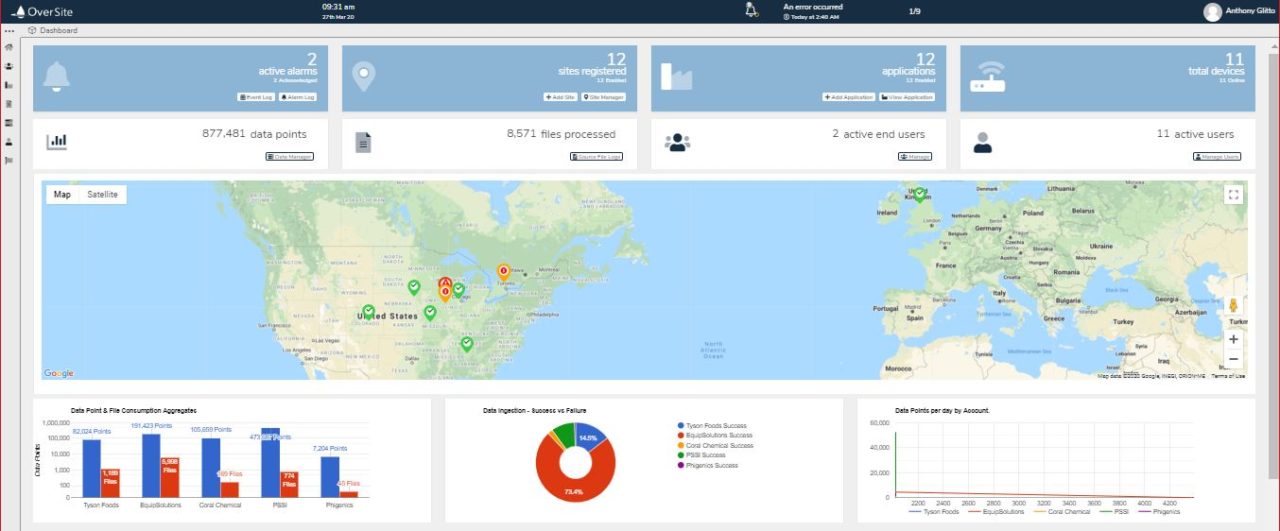

EquipSolutions’ OverSite™ is a device agnostic, cloud-based data acquisition and process management portal. Users can log on to the highly secure website from anywhere in the world, to view, store and manipulate off of their process data and critical parameters.

OverSite™ Main Features:

1. Connect to multiple end point devices

2. Direct communication to end point device with remote access

3. Automatic report generation and delivery

4. Advanced service report capability

5. Real-time notifications and alarms delivered by text, email and IM

6. Continuous secure web-based data management and reporting

7. Real-time access and control of your critical process data

If you’re a Plant Operator, the OverSite™ dashboard gives you full visibility into chemical feed applications and a high level of awareness for the health of your entire operation. If you ever change chemical suppliers or equipment providers – No need to worry – as OverSite™ keeps track of all your process and supplier data.

If you’re a Water Treater – don’t work another day without this account management tool. OverSite™ will transform how you plan and prioritize your day – It lets you manage multiple sites from one location, and it brings a new level of productivity to your service calls, maintenance & benchtop tests.

The all new EquipConnect 2.0 is a state-of-the-art Internet gateway optimized for secure M2M Industrial Internet of Things applications, facilitating data acquisition management, remote monitoring and control of all field endpoint devices. Our Zero-Touch Technology provides secure, intelligent and global connectivity period.

• Full Remote Communications 24/7

• Device Agnostic (Compatible with all controllers)

• Superior security provided by an advanced firewall

• Zero-Touch Technology ensures true plug & play installation and setup

• Pre-activated, pre-programmed carrier agnostic SIM card included

• NEMA 4X Enclosure: 10.5”X 8.5”X 6.25”

• No Proprietary software required

We have taken 25 years of Polymer Activation knowledge gained across hundreds of industrial and municipality-based projects to bring you The Tempest 1.0, a powerful multi-stage mixing and monitoring system solution.

The system design provides the right type of mixing energy at the critical moment of initial wetting and tapers that energy through a multi-stage regime of hydrating zones. The net result is a fully hydrated polymer solution with maximum charge site exposure which assures optimized polymer usage and performance. This design gives you optimum performance by eliminating unwanted agglomerations, plugging and the costly mess of dealing with these issues.

Many Polymer feed and control stations are complicated and prone to frequent plugging and agglomerations. The Tempest’s system is simple, yet highly intelligent, with the ability to provide just the right mixing energy—manually or automatically—at just the right times through the hydration process. Also, like many of our solutions, The Tempest has flexible controls and its pump configurations can be adapted to fit other uses.

With our full understanding of polymer activation mechanics and The Tempest’s features are created to leverage those principles, agglomerations are prevented and fewer polymer chains are destroyed. This means less waste as fewer costly polymers are used from optimum performance.

Throughout the dilution process, water flow rate data is measured and fed back to the Tempest’s primary controller. It calculates, then adjusts the polymer pump for an ideal dilution rate. When problems like water flow loss, high/low concentrations, etc. arise, an alarm sounds and remedial measures can be made on the spot.